Schweißgeräte/Generatoren

für motorbetriebene Schweißgeräte

mit Stumpfschweißverfahren

Schweißgeräte/Generatoren

für motorbetriebene Schweißgeräte mit MSW-Schweißverfahren

Die Produktpalette von Sincro bietet eine der vollständigsten Auswahlen von Schweißgeräten/Generatoren auf dem Markt, mit über 20 Modellen in vier Serien (SW, ARC, ED, EA). Sie werden in Italien mit SCR- oder elektromechanischer Technologie gebaut und sind für das SMAW-Stickschweißen konzipiert, können aber auch als zuverlässige Wechselstromgeneratoren für Anwendungen vor Ort eingesetzt werden. Die kompakten, vielseitigen und intuitiven Schweißgeräte/Generatoren von Sincro gewährleisten Langlebigkeit und Leistung in anspruchsvollen Umgebungen.

>WAHL DER SERIE

SW-Schweißgeräte/Generatoren, die auf der SCR-Technologie basieren, sind das Ergebnis einer jahrelangen Entwicklung des Konstruktions- und Fertigungs-Know-hows unseres technischen Teams, auf der unaufhörlichen Suche nach der Umsetzung und Optimierung der Leistungen. Entwickelt auf synchronen bürstenlosen (SW-I500) und bürstenbehafteten (SW-F300 und SW-E220/E250) Maschinen, dank der elektronischen Regulierung des Schweißstroms sind diese neuesten Modelle für die schwersten Anwendungen wie Pipelines geeignet und garantieren eine ausgezeichnete Stabilität und Präzision des Schweißens und die höchste Kompatibilität mit jeder Art von

Elektrode. Neben den typischen Funktionen eines Gleichstromschweißgeräts (220 ÷ 500A) und eines Wechselstromgenerators sind sie auch mit einem Jump Starter und einem Batterieladegerät mit Verpolungsschutz ausgestattet. Weitere wichtige Funktionen sind: Hot Start, Arc Force und Anti-Stick. Die Polycarbonat-Frontplatte ist mit einer nützlichen Anordnung für die Fernsteuerung ausgestattet.

>2-polige DC (Gleichstrom) Schweißgeräte + AC Generator:

2-polige AC (Wechselstrom)-Schweißgeräte + AC-Generator:

4-polige DC (Gleichstrom) Schweißgeräte + AC Generator:

2-polige DC (Gleichstrom) SCR (Silicon Controlled Rectifier Technologie) Schweißgeräte + AC Generator:

4-polige DC (Direct Current) SCR (Silicon Controlled Rectifier Technologie) Schweißgeräte + AC Generator:

Wahl des Modells

(1) leichte Montagearbeiten. (2) Reparaturen, die Stromstärken von mittlerer Intensität erfordern. (3) Schweißen von Tischlerarbeiten vor Ort. (4) Schweißen mit hoher Komplexität an Öl- und Gaspipelines. (5) Schweißen von Rohren an zivilen und industriellen Verteilungssystemen. (6) Reparaturen, die Stromstärken von hoher Intensität erfordern.

Wahl des Modells

Die Bestimmung des richtigen Schweißgeräts/Generators hängt von der Anwendung, der Art der Elektrode und den Eigenschaften der Maschine ab.

-

Der erste Schritt besteht darin, den Haupteinsatzbereich zu bestimmen. Wenn Sie leichte Arbeiten ausführen müssen, ist ein elektromechanisches Modell geeignet. Bei schweren Schweißarbeiten sollten Sie sich auf ein Modell mit SCR-Technologie konzentrieren.

-

Die Wahl des Modells hängt auch von der Art der Elektrode ab. Wenn zum Beispiel zellulosehaltige Elektroden erforderlich sind, empfehlen wir unsere elektronischen SW-Modelle.

-

Lassen Sie uns schließlich auf die technischen Besonderheiten unserer Schweißgeräte/Generatoren eingehen. Arbeitet der Motor mit 3000/3600 oder mit 1500/1800 U/min? Nach dieser ersten Unterscheidung sollten Sie sich auf den Ausgangsstrom (Gleich- oder Wechselstrom), die Amperezahl, die Generatorleistung und alle anderen Daten konzentrieren, die in ihrer Gesamtheit ein bestimmtes Modell eindeutig definieren.

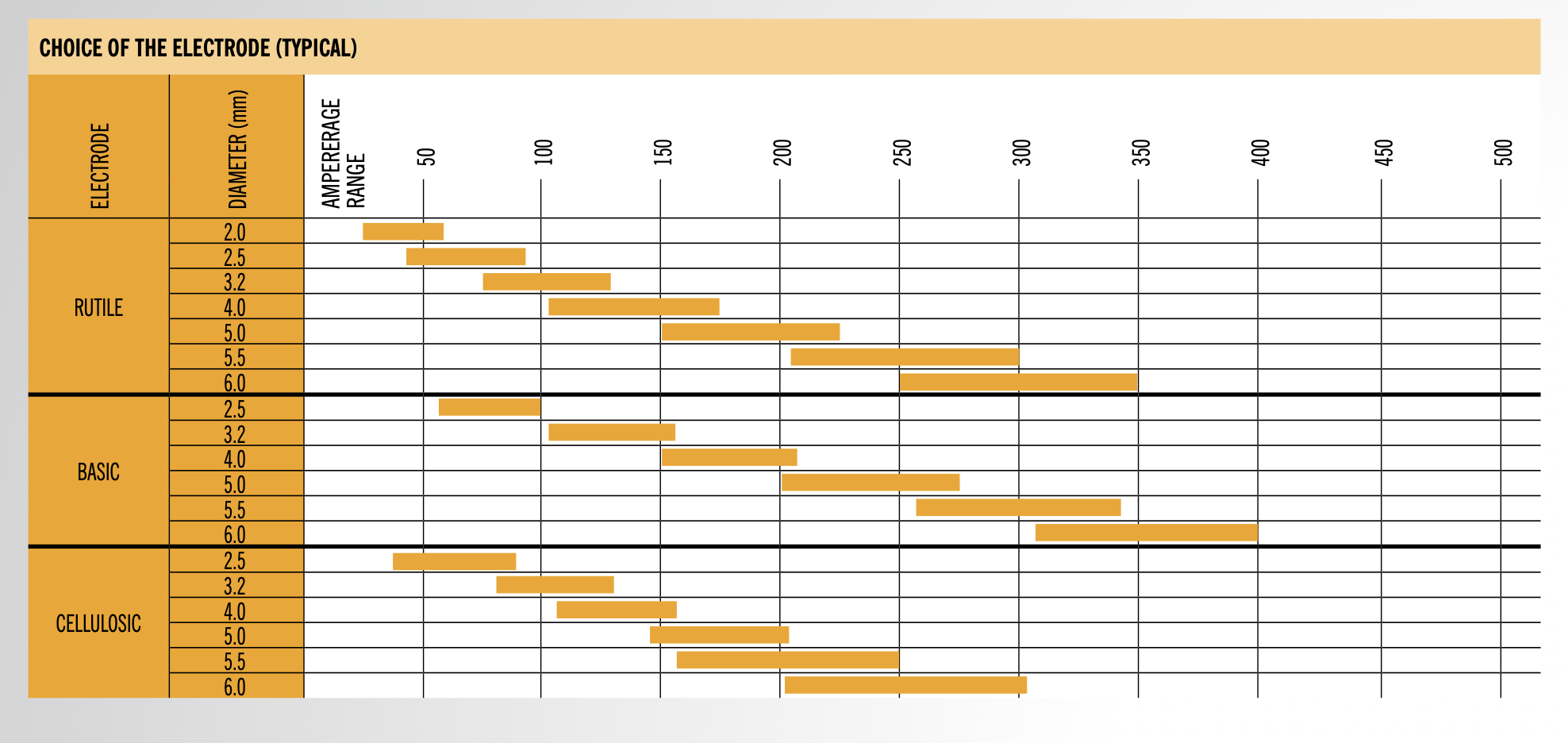

CHOICE OF THE ELECTRODE

Elektroden, die aus einem leitenden Metallkern bestehen, können viele Arten von Beschichtungen aufweisen, deren Zusammensetzung die Stabilität des Lichtbogens, die Abscheidung des Materials und die Reinheit des Bades beeinflusst, und werden in 3 Hauptklassen unterteilt:

-

Rutil (E6013): zum Schweißen in jeder Position, da es sehr einfach zu bedienen ist;

-

Basic (E7018): wenn Schweißungen auf hohem Niveau erforderlich sind;

-

Zellulosehaltig (E6010): typischerweise für Pipelines

Der Elektrodendurchmesser und der Schweißstrom (Ampere) sind voneinander abhängig.

Die in der nebenstehenden Tabelle angegebenen Durchmesser sind die international üblichen Durchmesser.

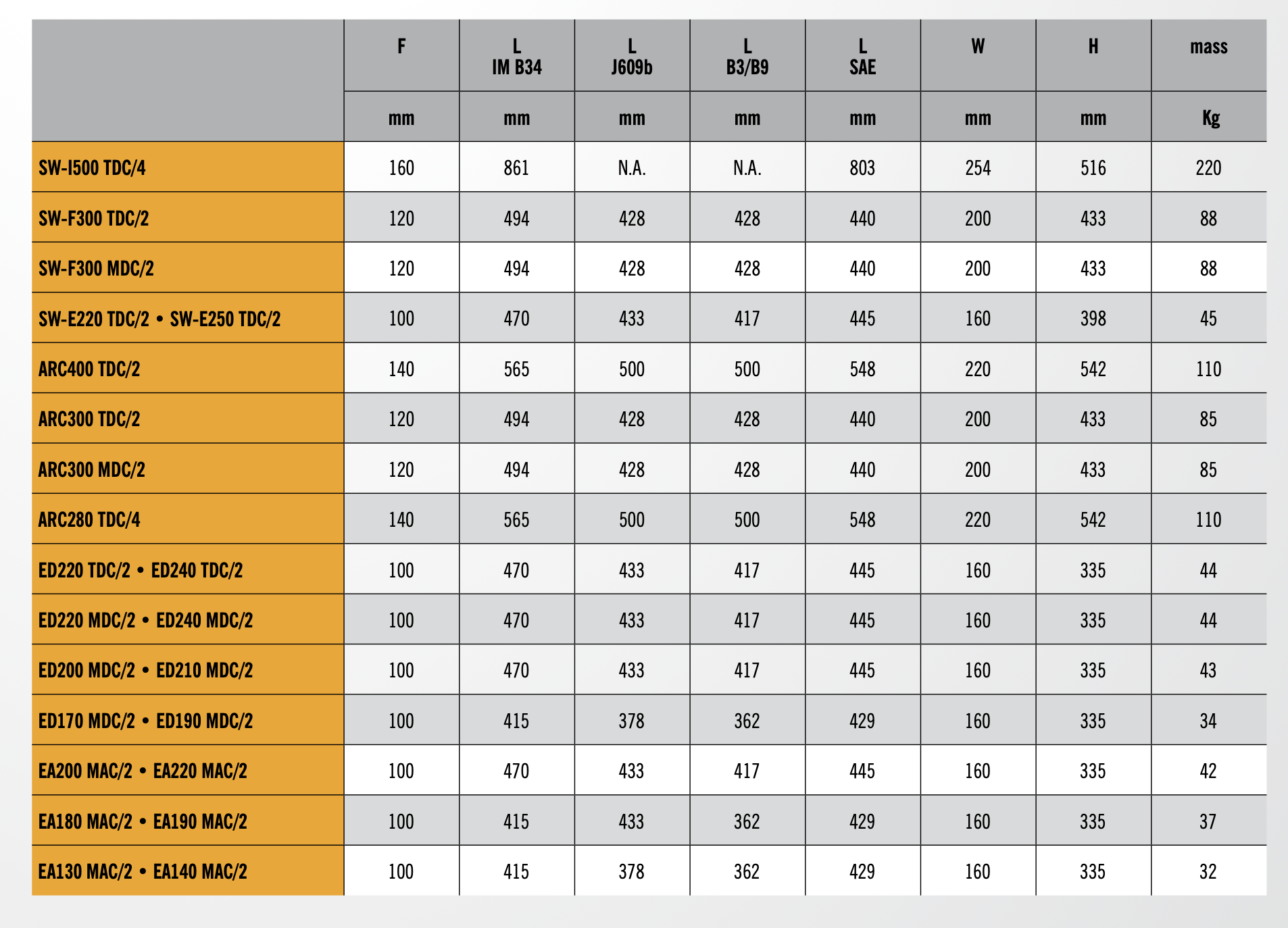

Gesamtabmessungen

Gewährleistungsbedingungen

Soga garantiert die eigenen Generatoren für einen Zeitraum von 18 Monaten ab Rechnungsdatum oder 12 Monaten ab der ersten Inbetriebnahme, je nachdem, was zuerst eintritt.

Wir bestätigen, dass sich die Garantie nur an Soga-Kunden richtet, denen wir antworten. Soga gewährt keine Garantie an diejenigen, die das Produkt nicht direkt von der Fabrik gekauft haben, obwohl sie es besitzen.

Im Rahmen der oben genannten Bedingungen verpflichtet sich Soga, kostenlos die Ersatzteile zu liefern, die nach ihrem Urteil oder dem eines bevollmächtigten Vertreters mit Herstellungs- oder Materialfehlern auftreten, oder, immer nach ihrem Urteil, die Reparatur direkt oder durch ein autorisiertes Zentrum durchzuführen, ohne Transportkosten zu übernehmen. Wir schließen auf jeden Fall Formen der Verantwortung oder Verpflichtung für andere Kosten, Schäden und direkte oder indirekte Verluste aus, die durch vollständige oder teilweise Nutzung oder unmögliche Nutzung der Produkte verursacht werden.

Durch die Reparatur oder den Ersatz wird die Garantiezeit nicht verlängert oder erneuert.

Die Garantie wird nicht gewährt: wenn Ausfälle oder Probleme aufgrund mangelnder Erfahrung, Nutzung über die Nennleistung hinaus, wenn das Produkt verändert wurde oder unvollständig, zerlegt oder mit

geänderten Typenschilddaten zurückgegeben wird.