Sincro ED-series Welders (170-240A) for SMAW Process + AC Generators 2-poles

€0.00

Sincro ED-Series 2-Pole DC (direct-current) brushes Welders/Generators – SMAW Welding + AC Generation IP23

The Sincro ED-Series is a robust line of Made in Italy 2-pole direct-current brush welders/generators, developed for stick arc welding (SMAW – Shielded Metal Arc Welding) and auxiliary AC power generation. Designed as a reliable power component for engine-driven welders, the ED-Series is the perfect solution for on-site applicationswhere durability, simplicity, and versatility are required.

Key Features:

Dual function: DC welder and AC generator combined in one unit

Electromechanical technology – strong and reliable, ensuring precision and stability

Protection class IP23 – designed for outdoor and on-site environments

Compatible with the most common electrode types – rutile, basic, and cellulosic

Manually adjustable welding current – up to 21 steps for great precision (170 ÷ 220A range)

Integrated thermal protection with automatic reset against overloads

Alternator function – can be used as an AC generator when welding is not required

Lightweight and compact design – ideal for portable, easy-to-carry engine-driven welders

Made in Italy – high-quality construction with constant innovation in materials and processes

Available Models:

50Hz Models (Europe, Asia, Africa):

ED190 MDC/2 – 170A DC output

ED210 MDC/2 – 200A DC output

ED240 MDC/2 – 220A DC output

ED240 TDC/2 – 240A DC output (3-phase version)

60Hz Models (North & South America, select regions):

ED190 MDC/2 – 190A DC output

ED210 MDC/2 – 210A DC output

ED240 MDC/2 – 240A DC output

ED220 TDC/2 – 220A DC output (3-phase version)

Applications:

Pipeline welding and field repairs

Civil engineering and construction sites

Agricultural and industrial equipment maintenance

On-site auxiliary power generation

Why Choose the ED-Series?

The ED welders/generators are recognized worldwide for their strength, reliability, and precision. Constantly improved with new components, advanced materials, and modern production processes, the ED-Series has become a benchmark in the market — an absolute must-have for customers seeking long-lasting performance and flexibility in the field.

Technical Specifications

|

MODEL |

ENGINE RPM |

ENGINE HP (SUGGESTED) |

DC WELDER A 35% |

DC WELDER A 60% |

AC GENERATOR KVA (S1) |

FRAME SIZE (MM) |

|

ED170 MDC/2 |

3000 |

9,5 |

170 |

130 |

3 (230V 50Hz) |

100 |

|

ED190 MDC/2 |

3600 |

11 |

190 |

140 |

3,5 (240V 60Hz) |

100 |

|

ED200 MDC/2 |

3000 |

11,5 |

200 |

170 |

4 (230V 50Hz) |

100 |

|

ED210 MDC/2 |

3600 |

13 |

210 |

170 |

4 (240V 60Hz) |

100 |

|

ED220 TDC/2 |

3000 |

- |

220 |

170 |

6,5 (400V 50Hz) + 3,5 (230V 50Hz) |

100 |

|

ED240 TDC/2 |

3600 |

- |

240 |

180 |

7,5 (480V 60Hz) + 3,5 (240V 60Hz) |

100 |

|

ED220 MDC/2 |

3000 |

- |

220 |

170 |

5 (400V 50Hz) |

100 |

|

ED240 MDC/2 |

3600 |

- |

240 |

180 |

5,5 (480V 60Hz) |

100 |

*ENGINE RPM – Recommended engine speed for operation, *ENGINE HP (SUGGESTED) – Minimum engine horsepower required, *DC WELDER A 35% – Maximum welding current at 35% duty cycle* DC WELDER A 60% – Welding current at 60% duty cycle, *AC GENERATOR KVA (S1) – Continuous power output as alternator, *FRAME SIZE (MM) – IEC mechanical frame size of the machine

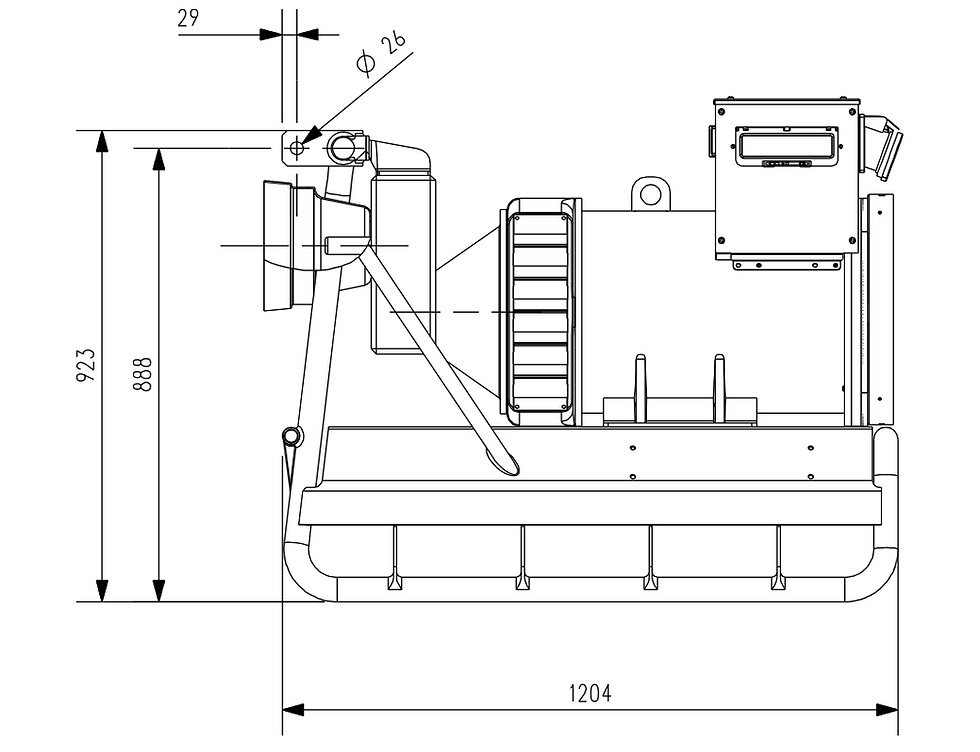

Dimensions

415mm x 224mm x 335mm

*Dimensions may vary depend on couplings.

Catalog

Download main catalog "Welders/Generators for engine-driven welders with SMAW welding process"

Detailed information about the ED series: